| Special Bearings | Products | |||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Copper Alloy Sprayed Coating CS100 | |

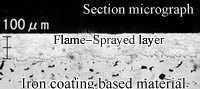

| CS100 is a copper-lead alloy sliding material

applied on the base material through the

flame-spraying method. While Cu CS100, copper-lead alloy thermal sprayed coating, has the lead finely and evenly distributed on the base copper material. With this, CS100 accomplishes a superior wear and seizure resistance that is durable under critical lubrication conditions that could never be accommodated before. |  |

|

|

|

Features and Effects As the sliding material is developed through the flame spraying method, an inexpensive steel and iron coating based material can be utilized, which contributes toward a low-cost designing solution.

|

|

|

Application Example Continuous and variable capacity swash-plate type car air-conditioner compressor swash plates ..... CS100 sprayed on the sliding surface of a cast-iron mother material | |

|

|

|||||||